Smart Inspection of Each and Every Screw and Nut; San Shing Fastech Uses AI to Implement Zero-Defect Management

Imagine a car driving down a highway. What would happen if an internal component were to suddenly fall off? Loosing a minor part would affect vehicle performance; but if the part is critical, it may endanger personal safety. Chen Xin-zhi, general manager of San Shing Fastech Corp, points out that this is why car makers have such strict requirements on the quality of their suppliers’ products, “especially the screws and nuts that connect and keep the parts of the car together. Automotive manufacturers even require ‘zero-defect,’ which poses serious challenges for quality inspection and control at suppliers.

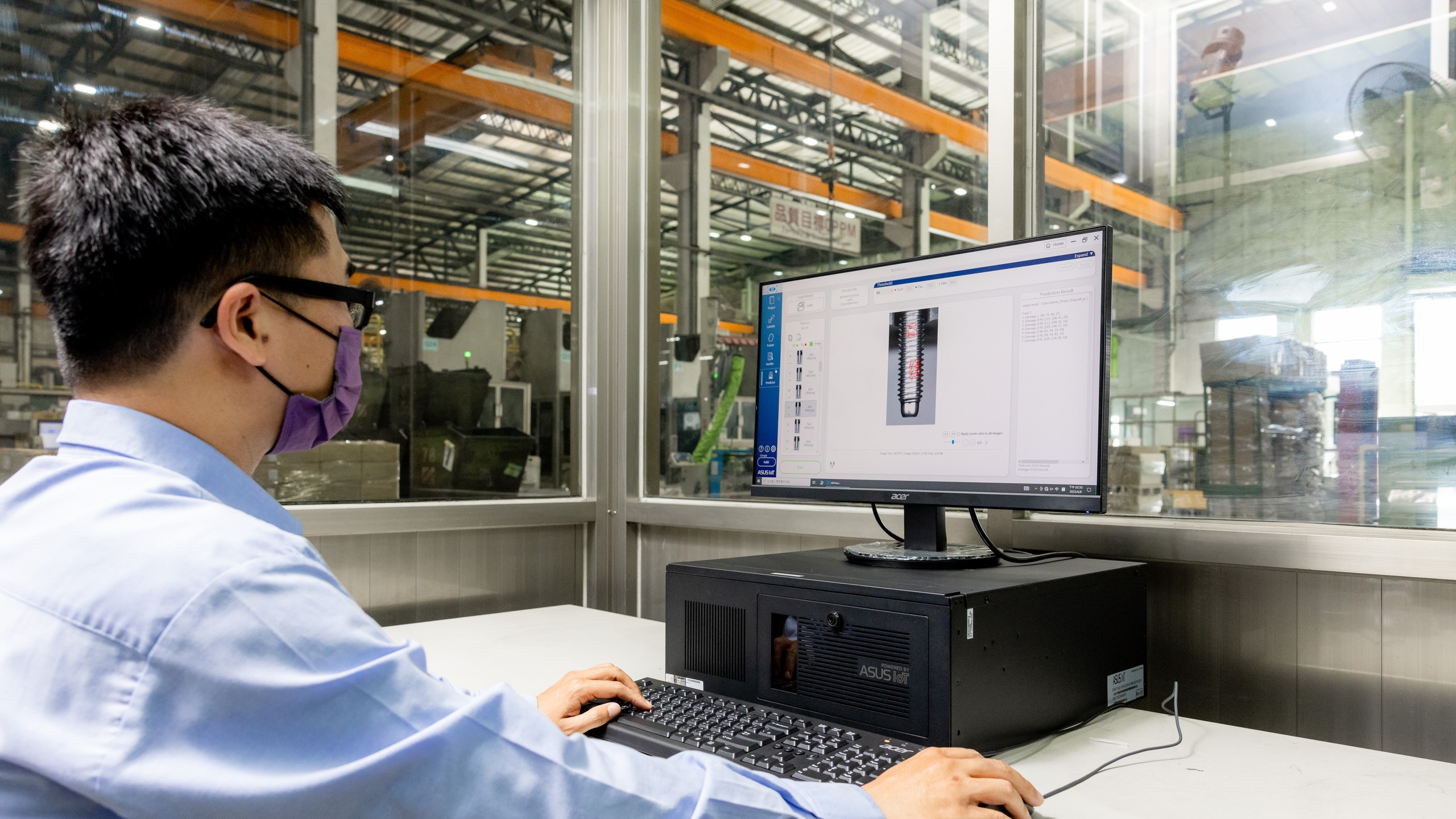

To that end, San Shing Fastech worked with ASUSTeK Computer to introduce ASUS AISVision in 2021. This AI machine vision toolkit not only boosts quality inspection efficiency, but also led to the company's R&D team being able to create an AI-powered visual inspection system.

One of Taiwan's unsung heroes, San Shing Fastech applied alternative business thinking to find its way out of the red ocean market

Established over half a century ago, San Shing Fastech is a global leader in the nut industry, with a monthly production capacity of 7,500 metric tons. It makes more than just fasteners, it also makes molds for self-tapping screws and nuts. It is top in the world in automotive nut output, and it is one of the unsung heroes of Taiwan. San Shing Fastech has always had a far-reaching vision for development. Early on, it decided to exit the red ocean market and devote itself to high-value automotive screws and nuts. Although their field did not require them to engage in price competition, there were still certain pressures and challenges they had to face, namely—product quality.

As mentioned above, automotive manufacturers require "zero defect" for their screws and nuts, meaning all types of shape deviations that are difficult to distinguish using the naked eye and blemishes that do not appear as if they would affect performance must all be rejected and returned. Chen points out how automotive manufacturing is now highly automated. If there are defects in screws and nuts that make them unable to be assembled in the automated process, the entire production line will be shut down immediately. “Which is to say, if we don't inspect them, the vehicle manufacturer factory will. And if something goes wrong, our suppliers will suffer greater losses, and it will damage our reputation."

For the zero defect requirement of the automotive factory, San Shing Fastech used manual inspection in its early stage, before bringing in external technical support to train its internal team to develop its own AOI (automated optical inspection) visual inspection system capabilities. Traditional AOI visual inspection systems adopt a rule-based model. In the initial stage of system building, defect types are first set according to existing experience, and defective products are eliminated immediately when found during inspection. Yang Yao-long, manager of San Shing Fastech’s R&D Department, points out that a rule-based visual inspection system has two major disadvantages: The first is that the system cannot detect defects other than those originally set, making it difficult to deal with random defects in the production process. The second is that, in order to achieve zero defect, there must be strict detection conditions. Yang says, "It is better to reject one hundred defects by mistake than to let one defect make it through inspection. This makes the false positive rate very high, resulting in a large number of good products being discarded, which in turn keeps production costs high."

In recent years, the AI trend has returned and has made its way into manufacturing. San Shing Fastech believes that the AI and AOI integrated smart detection system is the solution to these problems. After a round of market research, San Shing decided to cooperate with ASUS. Chen mentions several reasons why ASUS was chosen out of the many AI manufacturers. First, ASUS has a sufficiently large scale and can ensure long-term service. Second, it has the right level of professional technology and experience helping companies adopt these technologies. Chen says that the threshold for adopting industrial AI solutions remains high, and software and hardware solutions must be able to effectively meet the specific needs of users. That is why, in their early communications, San Shing raised the issues and ASUS provided the solutions, thus ensuring that their professional experience could actually solve San Shing’s pain points.

Caption: Chen says that for San Shing Fastech, ASUS AISVision is like a seed for AI. The seed will grow and bear the first fruits of AOI detection.

The third is that ASUS AISVision has secondary development functionality. Chen mentions that San Shing has long emphasized that it makes its own equipment. As mentioned, San Shing’s molds for screws, nuts, and various manufacturing equipment are not relegated to other manufacturers. The same is true for its AI AOI. ASUS' solution "teaches a man to fish rather than giving a man a fish." That is, it provides self-sufficiency. The AISVision machine vision toolkit and SDK support secondary development, so the San Shing R&D team was able to take over the integration, upgrading, revision, and maintenance of the in-factory IT system sorting equipment.

Traditional AOI has a high false positive rate. Can AI can actually identify flaws by itself?

Ku Ying-Hsien, Deputy Division Director of ASUS Computer’s Smart Manufacturing Solutions Professional Planning Department, points to the complicated AI application architecture used in many solutions on the market. Thus, to lower the threshold to entry, ASUS AISVision integrated the multiple tools required by industrial customers into a single platform, which greatly simplified secondary development and, with that, sped up system launch times.

Caption: Ku Ying-Hsien, Deputy Division Director of ASUS Computer Smart Manufacturing Solutions Professional Planning Department, points to the complicated AI application architecture used in many solutions on the market. Thus, to lower the threshold to entry, ASUS AISVision integrated the multiple tools required by industrial customers into a single platform.

Looking at San Shing Fastech’s system as an example: when constructing the training data set, the auto labeling function of ASUS AISVision can help the San Shing team to quickly complete defect identification of a large number of defective product images. An effective model was established in the training model; and lastly, this logic was transferred to the AI AOI system on the production line. The system’s inference model the system can not only judge defects, AISVision also has the ability to learn. With the accumulation of data sets, the model is continuously retrained and optimized to go beyond the older rule based AOI that presented many issues: it was not easy to adjust, needed strict test conditions, and resulted in a high false positive rate.

Aside from AISVision’s complete functionality, the main reason for the system launching so smoothly was the service provided by ASUS. Chen said that those who operate and use the AOI system are all OT personnel, so they are not necessarily familiar with AI. Continuous education and communication are thus necessary during the introduction stage. ASUS has assisted many different manufacturing industries introduce AI systems, so it fully understands the challenges that will be encountered at this stage, and it knows the solutions to those challenges. With the joint efforts of the ASUS and San Shing R&D teams, the software and hardware were established without a hitch.

Let AI connect the entire production line. ASUS assists with the first step!

Caption: The auto labeling function of ASUS AISVision can help the San Shing team to quickly complete defect identification of a large number of defective product images.

San Shing Fastech's AI AOI system just officially launched in May 2023; and they are starting to see the benefits of AI smart detection. Regarding future plans, Yang says that he will hand over AI system training to the front line. "We hope that the production line personnel have gained enough expertise with AI so that later they can adjust the structure according to their needs. And they can judge the results using on-site defect data and then repeatedly train the AI to raise the judgment accuracy of the AI." And as for long-term plans, they want to extend the AI architecture to the front end of the production line to record and analyze data like torque and vibration of equipment. While adjusting equipment parameters and improving yield, this function can also prevent defective products from entering the process down the line, further reducing unnecessary cost.

Chen says that for San Shing Fastech, ASUS AISVision is like a seed for AI. The seed will grow and bear the first fruits of AOI detection. "I think this will inspire other departments to imagine what they can do with AI, to think about how to use AI as a helper, to improve work efficiency, and kick off another round of upgrading. And that will help San Shing maintain its competitive edge."