ASUS PE8000G Autonomous Vehicle Computer Uses Intel CPU and GPU

Edited and reported by Intel

The PE8000G edge AI computer uses Intel® Core™ processor and Intel® Arc™ GPU for the Edge to deliver real-time AI training and inference for agricultural and manufacturing autonomous vehicles.

The core technologies that enable autonomous vehicles—sensors, artificial intelligence, edge computing, connectivity, and more—have matured significantly in recent years, creating a robust foundation for real-world deployment of these vehicles in a wide range of application including agricultural and manufacturing settings.

LiDAR, RADAR, ultrasound, multiple cameras, computer vision, and Global Navigation Satellite System (GNSS) technologies, among others, now offer the precision and reliability needed for real-time environment mapping and navigation. Simultaneously, advancements in AI and machine learning allow vehicle-based computers to perform perception and make complex decisions, adapt to dynamic environments, and optimize task execution.

The proliferation of 5G and private wireless networks has enhanced vehicle-to-system and vehicle-to-vehicle communication, while the rise of in-vehicle computing enables faster processing with lower latency. These converging technologies are reaching a level of reliability and cost-effectiveness that supports the scalable deployment of autonomous systems beyond research labs and pilot projects.

Adoption in Agriculture

Autonomous vehicles in agriculture are increasingly being adopted to address labor shortages, improve efficiency, and optimize precision farming practices. Self-driving tractors, robotic harvesters, and smart sprayers are currently in use across various farming operations. These machines not only reduce the manual burden on farmers but also enhance yield quality through data-driven field operations.

Use in Manufacturing Environments

In manufacturing, full-sized vehicles retrofitted to run autonomously and are used extensively in mining and warehousing applications and to transport workers. The PE8000G supports the vehicle data collection needs of these systems.

The in-vehicle computer that enables autonomy must have the I/O capacity to integrate the sensors and other perception technology inputs. It must also have the compute power for both real-time dynamic planning and large scale data training and inference. Often this requires a compute system with both high-performance CPUs and GPUs.

To enable autonomous industrial and agricultural vehicles, Intel® Industry Solutions Builders Partner Asus has developed the PE8000G, the company’s powerful AI edge computing system.

Ruggedized, High-Performance AI Computers

The PE8000G family of computers are ruggedized AI edge systems that support dual, high-end GPU cards and a variety of perception sensors or capture cards.

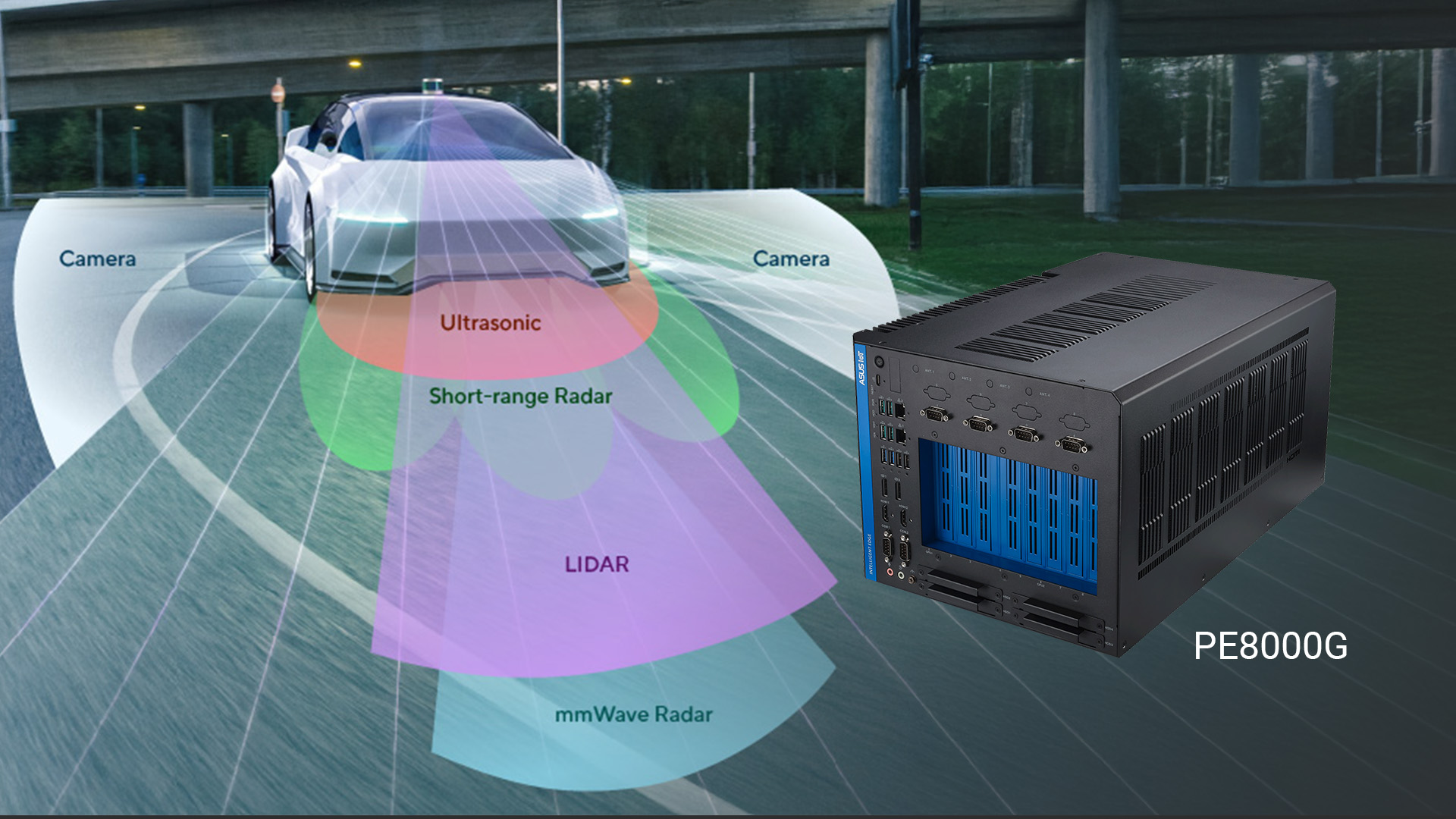

A typical use case can be seen in Figure 1. To get a full 360-degree view of the activity around a vehicle, the autonomous driving computer must support multiple cameras, millimeter wave (mmWave) RADAR, LIDAR, infrared sensors, ultrasound and short-range RADAR. All of this data must be processed in the computer in real time.

The PE8000G product family is based on 12th Gen, 13th Gen and 14th Gen Intel® Core™ processors. This broad family offers customers a number of options that allow them to select a system with the right balance of performance and power consumption for their application. The ASUS PE8000G incorporates a unique thermal design for heat dissipation.

Built in connectivity options include Wi-Fi, 4G/LTE and 5G NR wireless connectivity, and copper 1GbE port (Intel® i219 LM) and a 2.5GbE port (Intel® i226IT) for wired Ethernet connectivity.

In addition, the PE8000G is able to handle an 8 V - 48 V DC input range and offers built-in ignition power control and monitoring for flexible power options in diverse deployment scenarios. The PE8000G meets the MIL-STD-810H shock and vibration resistance standard and is engineered to withstand a high vibration intensity, making it suitable for rugged and demanding environments.

Compute Performance from Intel

The PE8000G computers offer high compute performance for multi-core processing and control decision based on the Intel Core processors and real-time inferencing performance from Intel® Arc™ GPU for the Edge.

Intel Core CPUs integrate multi-core architectures, enabling simultaneous execution of multiple task, which significantly enhances performance.

The processors are based on Intel’s hybrid architecture that combines Performance-cores (P-cores) for demanding tasks with Efficient-cores (E-cores) for background and low-power operations, optimizing performance per watt and enabling smarter resource allocation.

In addition, Intel Core processors can intelligently manage power and thermal demands through technologies like Intel® Turbo Boost and Intel® Thermal Velocity Boost. These features automatically increase the clock speed of the processor cores when thermal and power conditions allow, delivering extra performance for demanding workloads.

Intel Core processors are also distinguished by support for fast data transfer between GPUs and solid state drives (SSDs) and AI acceleration for responsive computing experiences. Intel Core processors support fast DDR5 memory and are compatible with advanced connectivity standards like Wi-Fi 6E.

Dual GPUs Provide Edge Inferencing

For real-time edge inferencing, the PE8000G supports dual Intel® Arc™ A750E GPUs, which are members of the Intel Arc GPU for the Edge product family. These GPUs can be used for edge inferencing, offering benefits like high efficiency AI, visual computing, and media processing at the edge. The Intel Arc A750E Graphics offers 28 Xe cores delivering 229 trillion operations per second (TOPS). Each device has a maximum thermal design point (TDP) of 225 Watts.

The PE8000G makes use of the Intel® Distribution of the OpenVINO™ toolkit that features inference efficiency optimization techniques including model quantization, layer fusion, and hardware-level optimizations. OpenVINO Toolkit-optimized models can leverage the parallel processing capabilities of the Intel Arc A750E GPU, resulting in faster inference speeds. The Automatic Device Plugin (AUTO) allows for inference requests to be made based on the optimal CPU or GPU resource available, prioritizing latency or performance as needed.

Conclusion

Asus has developed the PE8000G with the features and performance needed to convert human-driven industrial and farm vehicles into autonomous vehicles. The PE8000G pushes versatile AI inference applications from laboratories to the in-field applications. With CPU and GPU performance from Intel, Asus has a system that can revolutionize industrial and agricultural processes.