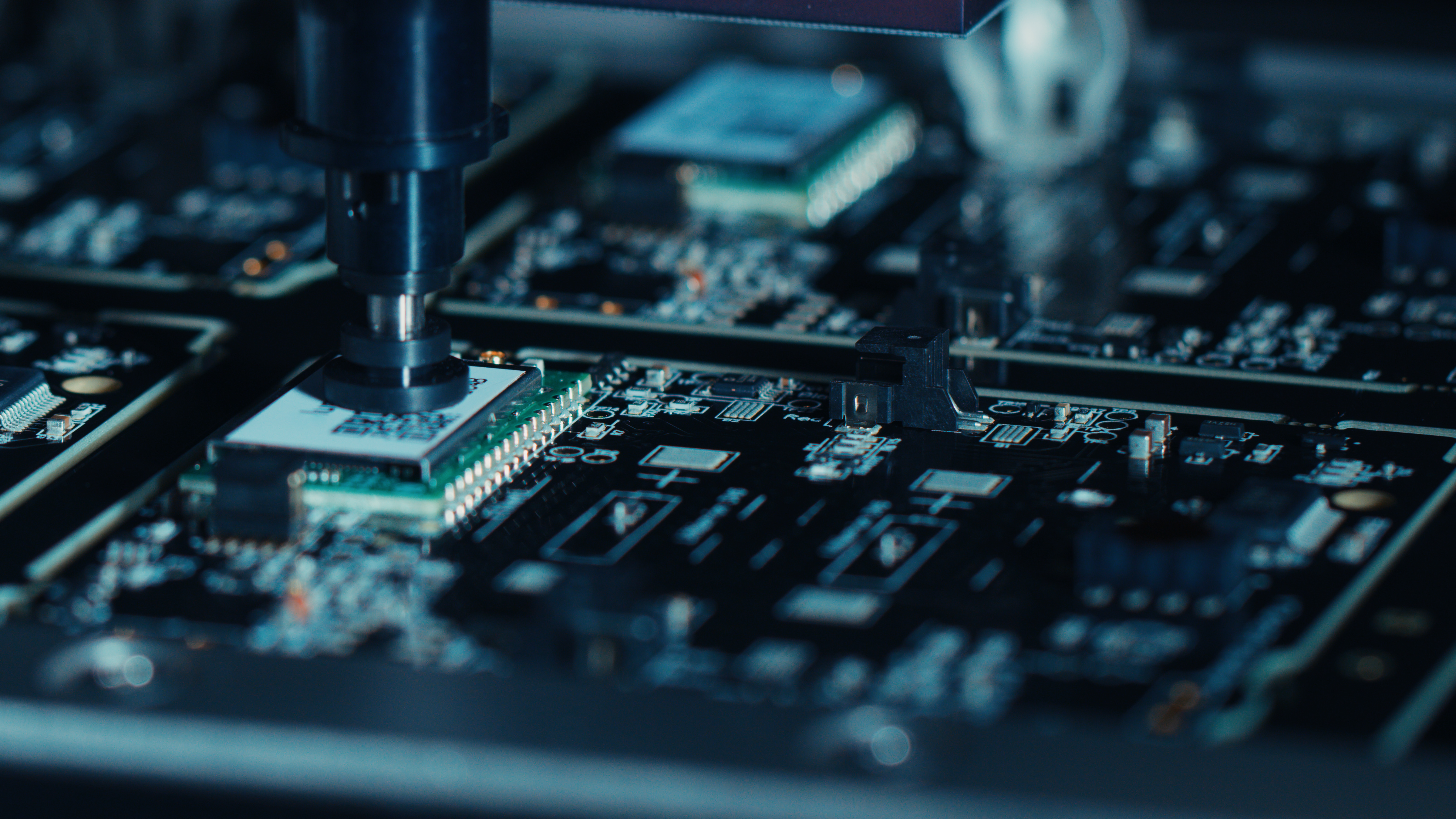

Unicomp and ASUS IoT Create High-Speed Computing, Massive Image Processing, and High-Performance X-Ray Inspection System

X-ray inspection is a widely adopted method of industrial radiography in many industries, particularly those in the manufacturing process, including quality control, precision inspection, and even scientific research using the data gained along the way. The latest incarnations of X-ray inspection integrate automation, high-speed computing, optics, and image recognition and processing. However, this integration is not trivial.

One 3D inline X-ray automatic inspection system, the LX9200, hails from Shenzhen’s Unicomp Technology. As a leading solution provider in this space, the company wanted to maximize the system’s capabilities, especially when performing multi-directional and multi-angle product inspection tasks. To achieve the goal, Unicomp required a high-performance image-processing core computer. In partnership with ASUS IoT, a leading manufacturer of high-end industrial embedded computers, Unicom was able to meet the diverse high-precision inspection needs of its customers.

Our Customer

Founded in 2009, Unicomp has actively strengthened its R&D capabilities and improved its ability to manufacture key components. As one of the world's leading manufacturers of X-Ray precision inspection equipment, Unicomp successfully upgraded the latest generation of its LX9200, providing the most innovative solutions for leading customers globally, in various manufacturing industries, including semiconductors, electronics, automobiles, new energy, and scientific research.

The Challenge: Navigating the Complexities of High-Speed AI Computing and Image Processing in X-ray Inspection Systems

Thanks to the rapid development of high-speed image processing, the technology has improved greatly in terms of image quality, speed, and inspection volume. Unicomp was also able to incorporate AI and machine learning into its large-scale precision inspection products.

The Unicomp design team believes that the use of AI will greatly increase the opportunities for unmanned factories that operate 24/7/365; at the same time, fully automating the complex manufacturing processes will inevitably promote automation of related quality management and precision testing. As a result, the demand for large-scale testing and full-time automated inspection will inevitably Increase.

The Solution: Powering Precision with the ASUS IoT EBS-4U700 Industrial Solution

To achieve its goals, Unicomp’s R&D team surveyed the latest available industrial-control units, finally landing on the ASUS IoT EBS-4U700 AIoT industrial solution, which is designed with an Intel® 13th/12th Gen. Core™ i9/i7 processors, DDR5 RAM, multiple display outputs, legacy options for industrial applications, COM ports, and three Intel LAN ports. All key system elements are powered by Intel® processors to deliver power-efficient performance and intelligence optimized for Industrial IoT (IIoT). ASUS IoT and Intel together offer scalable solutions that provide solid business results for Unicomp and lay the end-to-end foundation for their future smart factory.

Like the Unicomp R&D team, ASUS IoT believes that industrial-grade high-performance computers with huge data-processing capabilities (such as massive image processing) are required in a host of industrial applications. But the need to be more compact and with higher performance and reliability than what was previously available. One product that met those needs was the ASUS IoT EBS-4U700, contributed by ASUS IoT Configure-to-Order Services (ACToS) to meet customers’ rapid time-to-market requirements and production flexibility.

Unlike conventional industrial-control products, the EBS-4U700 is designed to operate with a high-power supply, and still fit into a compact and durable mechanical design. The designers applied the Common Redundant Power Supply (CSPR) standard for higher power supplies and to ensure that the LX9200 can perform the necessary high-speed and massive data processing tasks. ASUS IoT also equipped the EBS-4U700 with abundant SSD expansion slots for high-speed, high-volume data processing, while also maximizing I/O expansion.

Dealing With Excessive Heat

To cope with issues related to excessive heat, ASUS IoT and Unicomp teams jointly performed a series of thermal-analysis tests inside the EBS-4U700, then optimized the heat dissipation by changing the direction of heat flow. The ASUS IoT team also added a dust-proof design inside the EBS-4U700’s front panel as well as a cooling fan module, that assured the clean in-take air flow throughout the system. The forced air flow removed excess heat away from the GPUs, CPU, and SSDs, which enables the EBS-4U700 to operate under higher temperatures. Moreover, with the ASUS IoT Suite software, the EBS-4U700 can set the revolutions per minute (RPM), and configure the CPU and chassis fan speeds to fit different usage scenarios.

The Outcome: EBS-4U700 - Enhanced Performance and Optimal Heat Dissipation

Thanks to the high-performance and optimized heat dissipation of the ASUS IoT EBS-4U700, Unicomp was able to successfully upgrade its LX9200 to a powerful high- performance X-ray inline automatic inspection system. Without any extra mechanical re-design, the LX9200 was delivered with dual GPUs, capable of performing long-time, high-volume, high-precision inspection. With the LX9200, Unicomp’s customers have access to faster, more accurate, and higher quality inspection.