Flexible Robotic Solutions for E-Commerce Warehouses

E-commerce warehouses are popping up in almost every neighborhood. And the latest autonomous mobile robots (AMRs) that help facilitate the moving of goods within these warehouses are defined by advanced navigation, adaptability, and integration capabilities. These robots leverage technologies such as LiDAR, cameras, and AI-driven algorithms for precise mapping, obstacle avoidance, and real-time decision-making. Unlike traditional automated guided vehicles, AMRs have the ability to operate without a fixed infrastructure, offering greater flexibility in dynamic warehouse environments.

The global logistics landscape is currently grappling with a number of challenges, including increasingly complex environments and operational methods that need to be improved. At the same time, the relentless rise of e-commerce has created a need for faster deliveries and more efficient operations. This pressure has led to inefficiencies and burnout across the industry, where businesses are struggling to keep up with the growing demand for speed and accuracy. In the past, companies have addressed these issues by increasing their workforce and extending operating hours. However, this approach is not sustainable due to rising labor costs and an overall shortage of workers, especially in countries experiencing demographic declines. These realities have forced the industry to seek new, more sustainable ways to meet the demands of modern commerce.

As warehouses strive for greater efficiency and reduced operational costs, AMRs are becoming indispensable, offering fast ROI and adaptability to evolving e-commerce trends. However, challenges such as high initial investment and the need for robust cybersecurity remain areas of focus for continued technology advancements.

Key innovations include the collaborative AMRs that work alongside human operators, optimizing workflows like picking, sorting, and replenishment. For example, AMRs equipped with AI can efficiently cluster orders and reduce travel time, increasing overall throughput. Integration with warehouse management systems allows seamless coordination, enabling tasks such as inventory tracking and restocking to be automated.

Scalability is a notable feature, as AMR fleets can be expanded incrementally without significant infrastructure changes. Advanced solutions also incorporate swarm intelligence for task distribution and fleet optimization. Recent advancements focus on energy efficiency, extended battery life, and improved payload capacities. In addition, the use of 5G and edge computing is enhancing real-time responsiveness and connectivity.

Currently, many warehouses face significant challenges when adopting robotic solutions. The initial setup could require additional infrastructure, leading to high up-front costs, extended installation periods, and stabilization times. And warehouses frequently need to coordinate with multiple stakeholders, such as warehouse management system vendors, robot management platform providers, robot hardware manufacturers, and maintenance teams, making the implementation process time-consuming and increasing the risk at the initial stage.

Warehouse ARM With Limited Risk

One solution that fits the bill for this application is a platform that can be seamlessly deployed, operated, and maintained in any warehouse environment without additional infrastructure or facilities. Already being deployed in factories in South Korea, such a system is actually a bolt-on solution that offers the most optimal picking workflow, using intuitive robots that collaborate with human workers and real-time data to detect and determine any possible issues and long-term strategies.

The system being discussed here comprises two main components, an autonomous mobile robot, and an engine that manages the robots. The robot was optimized for both the physical environment of warehouses and the needs of the workers, and it collaborates seamlessly with the warehouse center. Its size and structure make it easy to integrate into existing workflows, while its intuitive functionality ensures an easy learning curve for users.

Equipped with both 2D LiDAR and 3D camera sensors, the robot offers precise autonomous navigation, obstacle detection and avoidance, and rapid mapping capabilities. These features are critical for warehouse centers, where space is often tight, and operations are fast-paced. And despite its advanced capabilities, the robot is offered at a price point that makes it accessible and cost-effective for businesses looking to enhance their warehouse operations without breaking the bank.

The second component, the manager/engine, acts as the workflow optimization platform, as it offers a range of management tools designed to streamline warehouse processes. It integrates seamlessly with clients’ warehouse management systems, enabling real-time order analysis and optimization. The platform also handles task allocation, fleet management of multiple robots, and provides advanced features such as a real-time monitoring dashboard and viewer. This dashboard lets operators track and respond to operations as they are needed, while the platform’s data insight capabilities enable companies to develop long-term operational strategies based on data analytics. The result is a warehouse that runs at peak efficiency while maintaining full visibility over its operation.

While other, potentially similar, solutions are available, the platform described here offers a unique simplicity and customer experience. Part of the reason for this is because everything has been designed and developed in-house, from the robot hardware to the software and platforms. Hence, warehouses deal with just one vendor and contact point, who handles everything from the initial warehouse analysis to the adoption, stabilization, operations, and ongoing maintenance.

The Brains Within the AMR

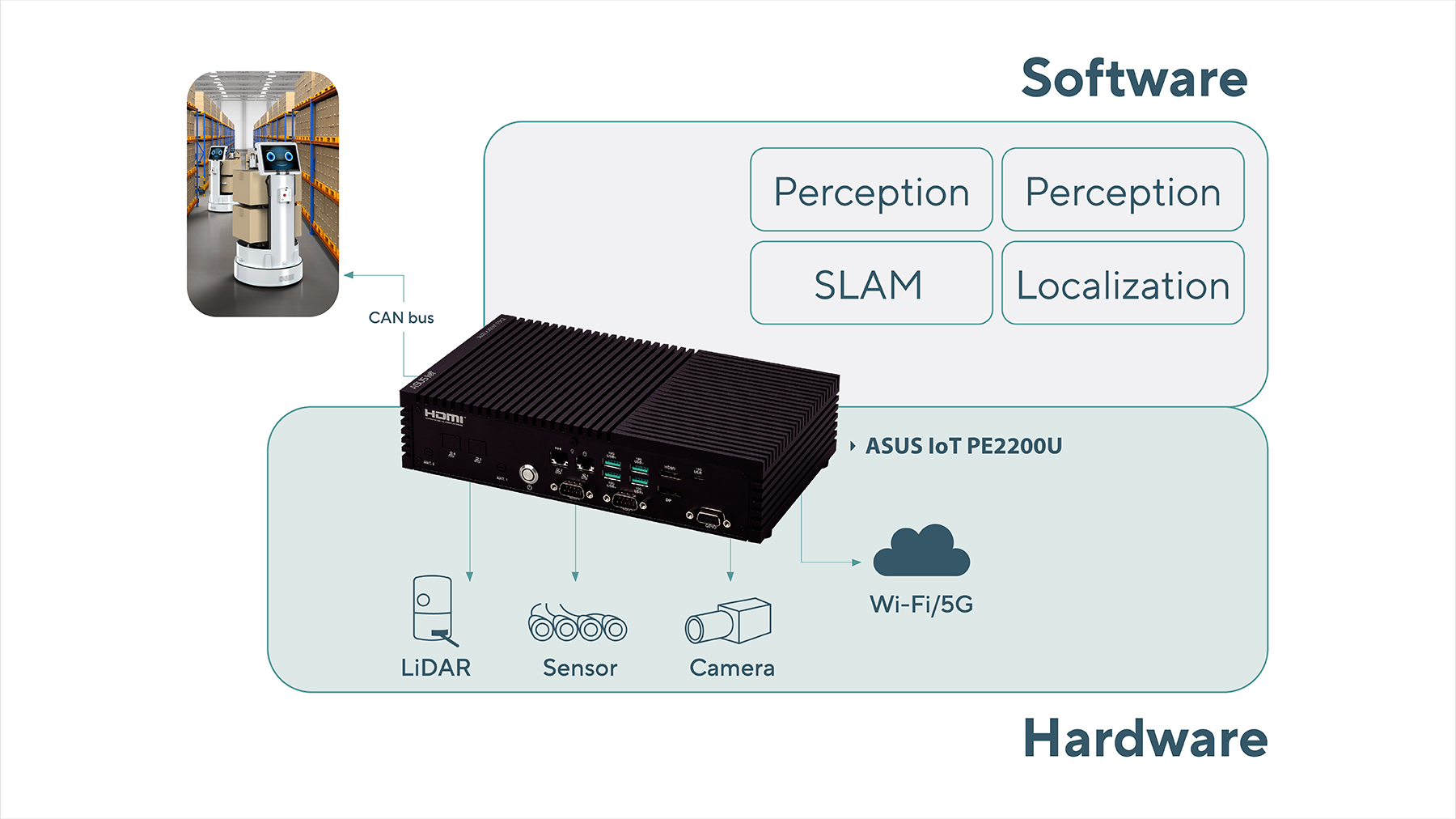

The main control computer within the robot is the ASUS IoT PE2000U. This embedded computer allows the robot to operate autonomously within warehouses, controlling various robotics programs, such as simultaneous localization and mapping (SLAM), computer vision, navigation, and sensor processing. These robotics programs operate based on a middleware called ROS2 that runs on the PE2000U.

The PE2000U is powered by Intel’s 12th Generation Core processor, codenamed Alder Lake, which features a hybrid architecture combining high-performance (P) cores and energy-efficient (E) cores for optimized multitasking and power efficiency. It supports DDR5 and DDR4 memory, PCIe 5.0, and advanced AI capabilities. The processor includes Intel Thread Director for intelligent workload management and improved performance. Built on the Intel 7 process, it offers higher clock speeds, better thermal management, and enhanced overclocking features.

The PE2000U’s innovative cooling system allows the platform to operate with just a heatsink rather than a fan, which is key for dusty environments like warehouses. That’s partly due to the low overall power consumption of the computer. From an input power perspective, it can operate from 9 to 36 V, providing lots of flexibility for integrators. In addition, the power terminal is constructed with locking-type connectors to withstand higher levels of vibration and shock, necessary for mobile robots, and resulting in a stable power supply.

When it comes to communications, the PE2000U provides ample RS232/485 serial, USB, and LAN ports, all common interfaces in robotics applications. And because antenna ports can be placed in multiple locations, there are fewer instances where cable routing is hindered by components placement within the robot.

To integrate the PE2000U into an application such as this one, power consumption is a key factor, particularly the computer’s low-power characteristics which enable long-term untethered operation. From a software perspective, CPU performance is crucial. Thanks to the PE2000U’s elevated CPU specifications, robotics software can operate quickly without issues.

ASUS Motherboards Help Maximize Productivity

The customer’s end goal was not to replace human workers with robots. Rather, it aimed to support and augment human efforts by using robotics to take over repetitive, physically demanding, or time-consuming tasks. This allows human workers to focus on more complex, creative, and meaningful work, contributing to higher overall productivity and job satisfaction.

And ASUS maintains a diverse lineup of single-board and embedded computers designed for robotics applications like those described here. Furthermore, each product line offers various CPU options, allowing manufacturers to select specifications according to their needs. The hardware also comes in various sizes, allowing products to be chosen based on specific applications.

ASUS IoT, a global leader in embedded computers, offers industrial motherboards with durable, industrial-grade components for reliable 24/7 operation in harsh environments and use in different vertical markets. Boasting a wide product selection, the company empowers a faster time-to-market by leveraging over 30 years of design-and-innovation expertise, world-class after sales service, the ability to respond rapidly to forecast changes, and long-term technical support. Contact them today.