Embedded Computers Ease Semiconductor Test Challenges

Semiconductor vendors face increasing demands for test handling equipment that must be fast, flexible, and capable of supporting a wide variety of device types and package sizes. With rising production volumes and rapidly evolving technologies, handlers must efficiently manage high throughput while maintaining precision and reliability. It’s also key to minimize equipment downtime, which can be costly to all parties.

To address these issues, vendors must provide more modular, scalable systems with robust architectures designed for durability, serviceability, and ease of integration with future technologies.

For example, to ensure reliability and scalability in semiconductor testing applications, vendors must design test systems with robust hardware, intelligent system monitoring, and modular architectures that allow for easy upgrades and expansion. Key factors include using industrial-grade components, implementing redundancy for critical systems, and designing for thermal efficiency and minimal wear under continuous operation. In addition, high levels of power efficiency are warranted to maintain component reliability and reduce operational costs.

In many cases, collaborative efforts with ATE manufacturers have led to standardized interfaces, improving compatibility across platforms. Over time, innovations such as robotic handling, thermal control modules, and vision-based alignment systems have enhanced performance and minimized operator intervention, helping semiconductor vendors meet evolving test challenges.

Supporting Today’s Semiconductor Test

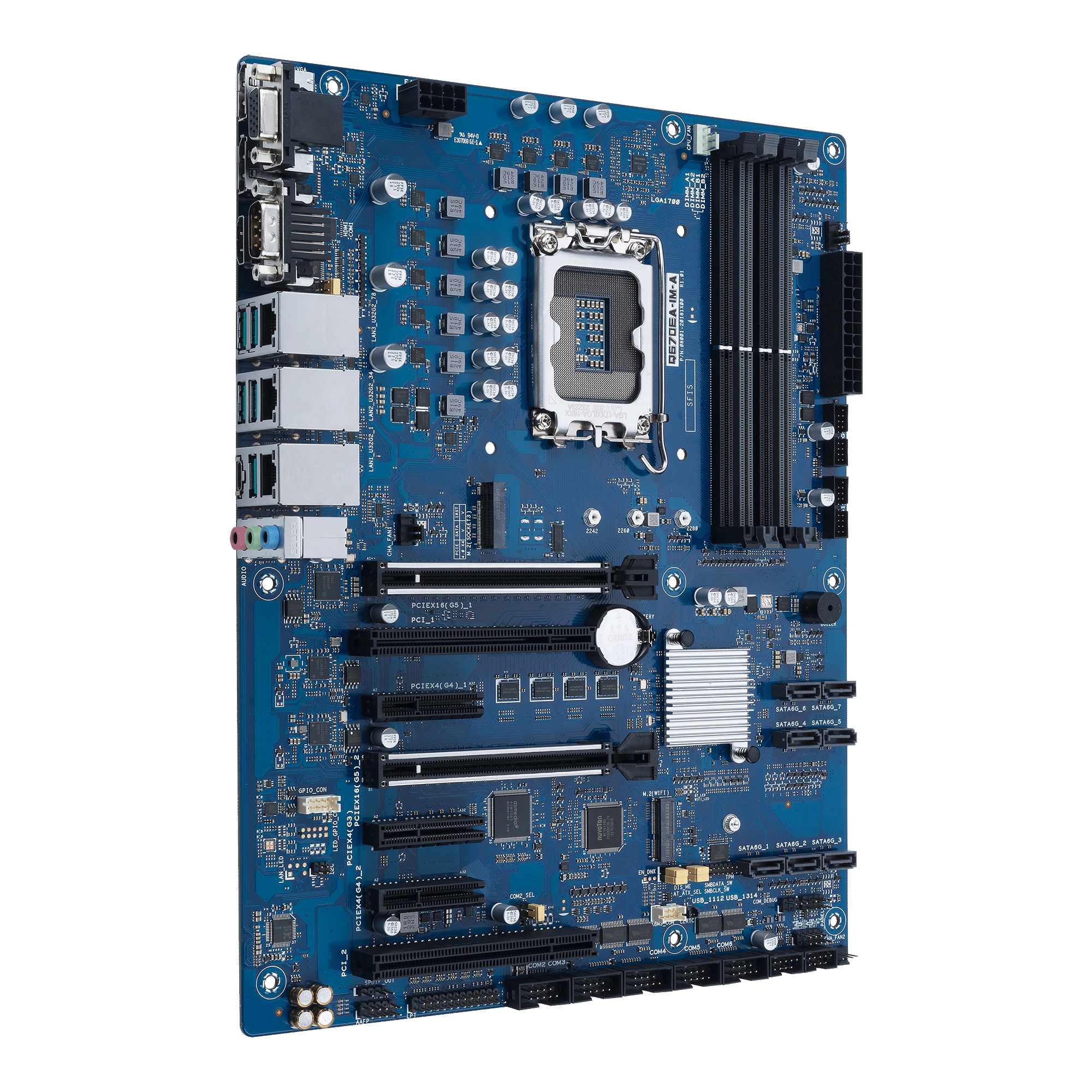

Today, lots of expansion is needed, particularly in semiconductor test, meaning that slots for add-in cards are a necessity. This recently became apparent when a semiconductor manufacturing company based in Malaysia needed a more scalable and reliable solution for its test handling machines to meet growing industry demands. Fitting the bill for the company’s needs was the ASUS IoT Q670EA ATX motherboard.

The high-performance board helped to achieve near-zero faulty-unit return rates by integrating enterprise-level durability features and extensive validation processes. It supports continuous operation through its use of high-quality components, reliable power delivery, and advanced cooling mechanisms. Its design includes a host of I/O options and memory support, providing the flexibility and scalability required for expanding test environments without replacing the entire system.

Modularity Is Key

To address these issues, vendors must provide more modular, scalable systems with robust architectures designed for durability, serviceability, and ease of integration with future technologies. To ensure that reliability and scalability in semiconductor testing applications, vendors must design test systems with robust hardware, intelligent system monitoring, and modular architectures that allow for easy upgrades and expansion. Key factors include using industrial-grade components, implementing redundancy for critical systems, and designing for thermal efficiency and minimal wear under continuous operation. In addition, high levels of power efficiency are warranted to maintain component reliability and reduce operational costs.

The ASUS IoT Approach

By adopting known, reliable platforms, vendors can build test handlers that are both durable and future-ready. The scalability enabled by the Q670EA’s expandability allows the integration of additional test modules, automation interfaces, or data acquisition systems as future testing needs evolve. This reduces downtime, simplifies maintenance, and extends the lifecycle of the equipment, ultimately improving cost-efficiency and production throughput.

Additional features of the Q670E ATX motherboard include support for a 12th or 13th Gen Intel CPU (up to 125 W), four U-DIMM slots for up to 128 Gbytes of 4.4-GHz DDR5 memory, and support for VGA, HDMI, and DisplayPort displays. The wide temperature range can operate from 0°C to 60°C.

Note that ASUS IoT provides extensive FAE support on a global basis throughout the customer’s design process with detailed testing and reporting back to the customer. Other benefits to ASUS IoT’s customers include enhanced system flexibility to support evolving testing requirements with easy expansion, and increased uptime and performance with the most reliable hardware.

The ASUS IoT Advantage

ASUS IoT is well suited to provide products for the semiconductor test space due to its emphasis on the features discussed here, including industrial reliability, scalability, and long-term support. The company’s platforms, such as the Q670EA ATX motherboard, are designed for long life, even under the most demanding conditions, featuring high-grade components, enhanced power delivery, and advanced thermal management to ensure exceptional uptime and performance consistency.

The company understands the pain points that need to be overcome by its customers. More importantly, it knows how to get passed those pain points, and solve the issues that arise along the way. For example, it might be the limited expansion capability of existing systems. Many test handlers offer a restricted number of expansion slots, which constrains the integration of additional testing modules or functionality, such as thermal control units or vision inspection systems. This limitation reduces flexibility and makes it difficult for manufacturers to scale or adapt their test setups to meet evolving product requirements.

ASUS IoT also offers rich expandability with multiple PCIe, I/O, and memory slots, which enables easy integration of test-specific modules such as data acquisition cards, thermal control units, or additional sensors. This flexibility allows vendors to build modular and scalable test systems that can adapt to different devices and future production needs without complete redesigns.

Moreover, ASUS IoT supports long product life cycles and provides enterprise-grade validation and support, minimizing risks associated with component obsolescence or unplanned downtime. The company’s platforms often include remote management tools, security features, and compatibility with industrial protocols, making them ideal for integration into automated and connected semiconductor testing environments.

In essence, ASUS IoT delivers the performance, durability, and adaptability required to meet the rigorous demands of modern semiconductor testing. It provides strong technical support and a deep understanding of its customers’ pain points, which is essential in delivering the most suitable motherboard solutions, tailored to meet specific application requirements and ensure long-term satisfaction.